OFFSHORE OIL & GAS PROJECTS

Fleetway Inc. and its affiliate Oceanic Consulting Corp. remains very active in Canada’s offshore energy exploration and production sectors. Fleetway’s current interests include support to the modeling and simulation on marine infrastructure, vortex-induced vibrations in riser pipes, and R&D to applied engineering studies impacting physical and numerical modeling of offshore structures and ship designs. Fleetway has a robust finite element modeling and analysis capability for equipment, system and whole-ship applications.

Eirik Raude Design Support

The Eirik Raude was a very large semi-submersible oil exploration platform. Irving Shipbuilding Inc. in Halifax completed the topside fabrication of the rig and Fleetway provided design and engineering support services across numerous technical disciplines. Fleetway provided work instructions, inspection specifications, non-destructive testing management and inspection services, welding technology, dimensional control and surveying, calibration management, quality records control, receiving inspection of material and equipment, quality control gap analysis and audits and quality documentation development.

Sable Off-Shore Energy Supply Chain

Fleetway was contracted by Sable Offshore Energy Inc. (SOEI) to provide Supply and Maintenance Services to the shore based production and fractionation plant, the four (4) offshore Production Platforms located off Sable Island and the connecting 140 kilometres of pipelines. Fleetway qualified and approved 650 vendors, generated 23,000 master material items, 2400 annual work orders and 3200 purchase orders and employed 55 maintenance personnel per day over the 6 year duration of the contract

The maintenance support work included the planning and scheduling of all work to coincide with the planned downtime, the provision of skilled trade’s persons and general labourers required for the care and custody of onshore facilities. This supply support work required the supply of all materiel required for the operation and maintenance of the gas production facilities as well as warehousing, inventory management, freight consolidation, work pack consolidation and staging, customs and brokerage and the control of shipping activities.

White Rose FPSO Design Engineering

White Rose is an FPSO whose hull was fabricated overseas and the top-side fabrication and load-out was conducted in Canada. Fleetway was contracted to undertake the project management and production engineering to support the fabrication of piping modules, the flare rack, and the expansion vessel. Fleetway worked to a very tight schedule completing the pipe support fabrication drawings which were immediately provided to the production team. Fleetway designers also developed the installation drawings and specifications for load-out onto the White Rose.

Hebron GBS Design Services

Fleetway was awarded a Marine Design Services and Marine Vessel Inspection Services by Kiewit-Kvaerner Contractors in support of the Hebron GBS design and fabrication project. The Hebron GBS Platform consists of a reinforced concrete structure designed to support the weight of the topsides production, accommodation and platform infrastructure, while being sufficiently strong to handle the meteorological and oceanographic conditions at the offshore site. The topside facilities comprise a process and utility module (housing all utility and production equipment), a drilling derrick, a drilling support module, living quarters, and ancillary equipment (flare boom, lifeboat station, and helideck).

The design services were comprehensive and variable in nature and included the design modification to support vessels, the preparation of stability calculations and booklets, the assessment of design changes to mitigate vessel motions and accelerations generated by environmental loads, mooring calculations for the GBS while in a flooded dry-dock, vessel modifications to install bulwarks/railing on tugs and barges, and the removal, replacement, and modification of existing equipment and the ballast system. The work also included calculations and data preparation required by the Classification Society.

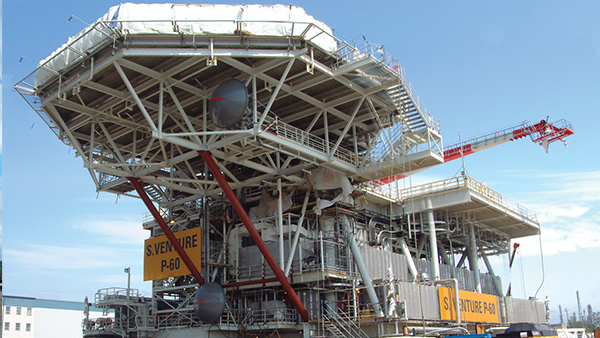

South Venture Topside Modules

Fleetway was involved in the South Venture Topside module design, fabrication, and quality control testing. The South Venture production rig, located off Sable Island was designed and built to conduct preliminary dehydration of the natural gas flowing from wells, for onward flow s to the Thebaud production rig. The on-site construction support work by Fleetway involved engineers, draftspersons and quality control specialists, all integrated into the overall production and installation team.